In the dynamic realms of industrial and consumer markets, the demand for versatile and high-performance materials has led to the widespread adoption of PETG (polyethylene terephthalate copolymer) films. PETG films have gained prominence due to their multifaceted nature and are available in two distinct surface finishes: high gloss and matte. Each finish possesses unique properties catering to varied application needs. This article delves into the nuanced differences between these two treatments to guide you in selecting the appropriate PETG film for your specific application.

High-Gloss PETG Film

What is High-Gloss PETG Film?

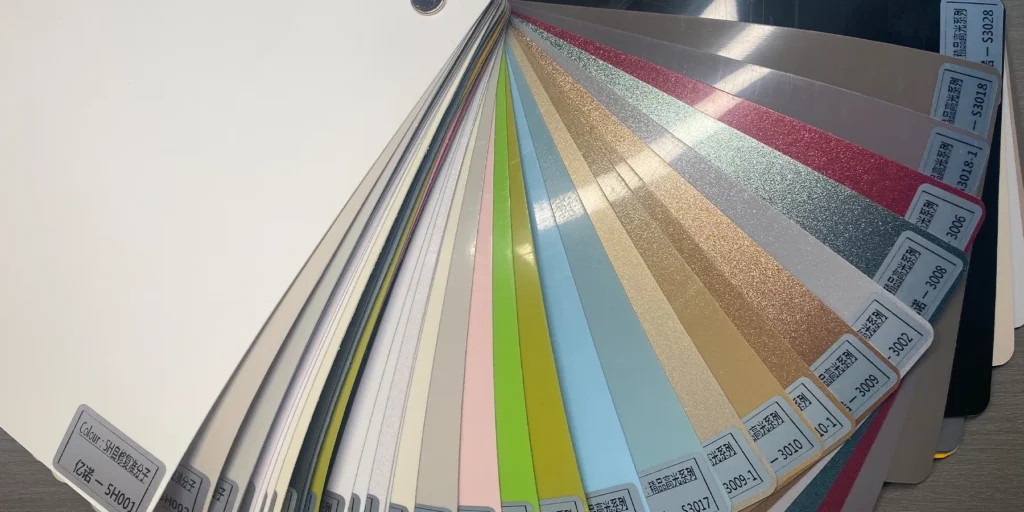

High-gloss PETG film, as its name suggests, boasts a smooth, shiny surface with a strong reflective quality. This finish is particularly favored for applications that prioritize visual appeal and impact.

Key Features of High-Gloss PETG Film:

- High Transparency: High-gloss PETG film offers excellent transparency, with a light transmittance exceeding 92%, making it ideal for optical applications.

- Smooth Surface: The film’s smooth texture enhances its tactile appeal and elevates the material’s overall aesthetics.

- Reflective Effect: The reflective surface amplification enhances visual effects, making products appear brighter and more vibrant.

- Ease of Cleaning: The smooth, polished surface prevents the accumulation of dust and dirt, simplifying cleaning and maintenance.

Matte PETG Film

What is Matte PETG Film?

In contrast, matte PETG film provides a non-reflective, subtle finish. This treatment is essential for applications that require reduced glare and a sophisticated presentation.

Key Features of Matte PETG Film:

- Anti-Glare Properties: The matte finish diffuses light to prevent reflections and glare, beneficial for displays and signage.

- Sophisticated Look: The non-reflective surface offers a professional, elegant appearance suitable for various aesthetic applications.

- Scratch Resistance: Matte finishes often exhibit enhanced scratch resistance, preserving the material’s look over time in high-contact scenarios.

- Tactile Appeal: The textural quality of matte PETG film can provide a pleasing, tactile experience, adding an extra layer of sensory appeal.

Comparing High-Gloss and Matte PETG Films

High-Gloss PETG Film:

- Advantages: Visual impact, high transparency, ease of cleaning

- Disadvantages: Prone to fingerprints and smudging, reflective glare may be undesirable in some settings

Matte PETG Film:

- Advantages: Anti-glare properties, sophisticated and professional appearance, higher scratch resistance

- Disadvantages: Lower visual impact compared to high-gloss finishes, can be harder to clean due to the textured surface

Selecting between high-gloss and matte PETG films boils down to understanding the specific requirements of your application. High-gloss PETG film is perfect for applications necessitating visual brilliance and ease of maintenance. In contrast, matte PETG film is ideal for environments requiring reduced glare and a more professional, subdued appearance.

What is the Difference Between High Gloss and Matte PETG Films?

When comparing high gloss and matte PETG films, several key factors highlight their distinct characteristics and suitability for various applications.

- Appearance and Visual Effects: High-gloss PETG film features a smooth, reflective surface that enhances brightness and creates a striking visual impact, making it ideal for high-end aesthetics. In contrast, matte PETG film has a subdued gloss level, resulting in a softer, more elegant look that conveys comfort and sophistication.

- Practicality and Maintenance: High-gloss films are easier to clean due to their smooth surface, which resists dust and dirt accumulation. However, they are more vulnerable to scratches and fingerprints. On the other hand, matte films offer better scratch and fingerprint resistance, though their textured surface can attract more dust, necessitating regular maintenance.

- Application Fields and Applicable Scenarios: High-gloss PETG is perfect for applications requiring high visual appeal, such as advertising, packaging, and luxury electronic products. Conversely, matte PETG is suited for settings where reduced glare and improved visual comfort are essential, such as electronic displays and architectural elements.

- Cost and Production Process: The production of high-gloss PETG films often involves additional treatments like polishing, which can increase costs. Matte PETG films, while still requiring specific molding processes, generally have lower production costs, making them a more economical choice for certain applications.

In summary, the choice between high gloss and matte PETG films ultimately depends on the desired visual impact, practicality, and specific application needs.