The number of plies in plywood refers to the layers of veneer bonded together to form a single sheet. This article explores the significance of ply count, its relationship to plywood thickness, and how it varies with materials and production regions. While the ply rule is commonly applied to Chinese hardwood plywood, it may not hold universally for plywood manufactured in other countries.

The Ply Rule in Chinese Hardwood Plywood

Why Count Matters

The number of plies in plywood impacts its strength, stability, and resistance to warping. Plywood typically has an odd number of layers (3, 5, 7, etc.) to maintain balance and minimize warping. By alternating the grain direction of each layer, manufacturers achieve greater rigidity, especially perpendicular to the surface grain.

Material Considerations

Chinese plywood, particularly poplar core plywood, is known for its thin veneers, which allow flexibility in ply count without drastically increasing the thickness. This distinguishes it from plywood produced in other countries such as Malaysia, Indonesia, Russia, and the United States, where different materials like pine, birch, or eucalyptus are used. These materials often result in variations in the ply rule.

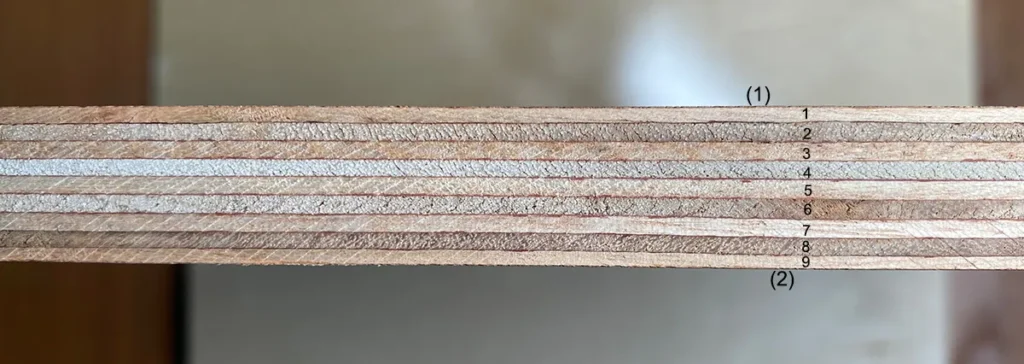

Ply Count and Thickness in Chinese Plywood

The relationship between ply count and thickness is well-defined in Chinese poplar plywood. Below is a general guideline for the number of plies based on thickness:

| Thickness (mm) | Number of Plies (Including Face Veneers) |

|---|---|

| 2–3.2 | 3 |

| 3.6 | 3 or 5 |

| 4 | 5 |

| 5.2–6.5 | 5 or 7 |

| 9 | 7 or 9 |

| 12 | 9 or 11 |

| 15 | 11 or 13 |

| 18 | 13 or 15 |

| 21 | 15 or 17 |

| 25 | 17 or 19 |

Common Ply Configurations

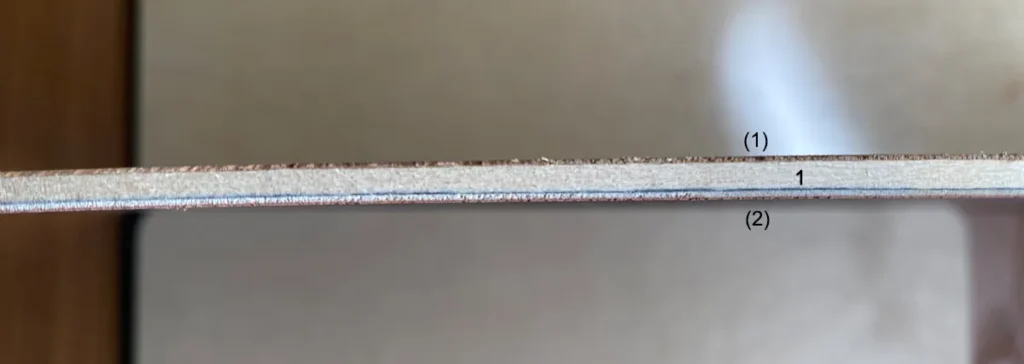

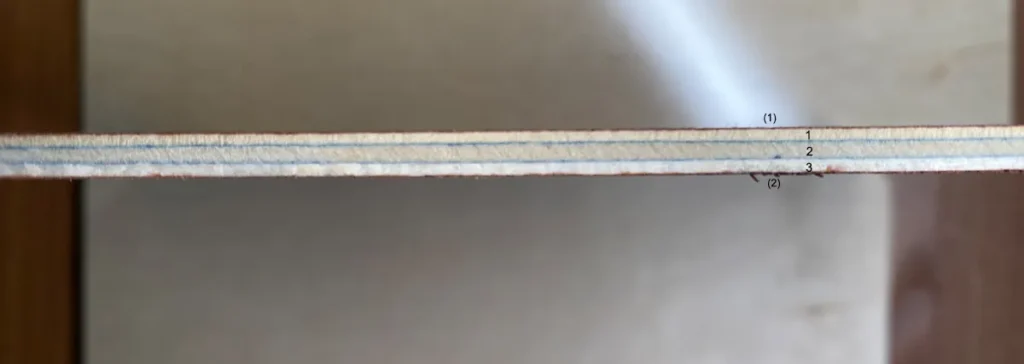

3-Ply and 5-Ply Plywood

- 3-Ply Plywood: Often used for thin, lightweight applications such as decorative panels or backing.

- 5-Ply Plywood: Offers improved stability and is suitable for furniture and cabinetry.

7-Ply and 9-Ply Plywood

- 7-Ply Plywood: Typically used in construction and medium-strength applications.

- 9-Ply Plywood: Common for flooring and durable furniture.

13-Ply and Beyond

- 13–19 Ply Plywood: Found in thicker panels (15–25 mm), suitable for heavy-duty applications like industrial flooring or structural components.

Why the Ply Rule Differs Globally

Plywood manufactured outside of China often deviates from the Chinese ply rule due to differences in:

- Veneer Thickness:

- Chinese factories use thinner veneers, allowing for higher ply counts without increasing thickness.

- Other countries, such as Russia and the United States, often use thicker veneers, reducing the ply count for similar thicknesses.

- Materials:

- Chinese plywood typically uses poplar, which is lightweight and flexible.

- Birch (used in Russia and Latvia) and eucalyptus (common in Indonesia and Vietnam) have higher densities, impacting the ply configuration.

Applications of Ply Count Knowledge

Understanding the number of plies is crucial for:

- Import Decisions: Buyers importing plywood from China can better assess product specifications and suitability.

- Design Choices: Higher ply counts generally offer more stability, making them ideal for precise or demanding applications.

- Cost Optimization: Knowing the relationship between ply count, materials, and thickness helps balance quality and price.

Conclusion

The ply count in plywood is a key factor that determines its strength, stability, and suitability for various applications. While Chinese hardwood plywood, particularly poplar core plywood, follows a clear ply rule, regional differences in materials and production methods mean that this rule does not universally apply. Buyers and users should consider both ply count and material composition when selecting plywood for their needs.